Last night I went to ACE hardware. (They actually know my name there now.) I bought a 7/16" threaded rod and some nuts and washers. I used the threaded rod as and axle and was able to bolt on the bike wheels. I drove the rod through a wooden frame made of 2X4's I cobbled together in about an hour. The project is a recognizable wheelchair now. I may need to adjust the spacing between the wheels in orde to give the user more room, but the tweaking is rather minimal. Vanessa is working on getting seat cushions ready and preparing a mannequin/scarecrow for our prosthetics demonstration. I will be focusing on attaching the back wheel(s) and working out those simple but inevitable bugs within every project. We are both very pleased with how everything is turning out.

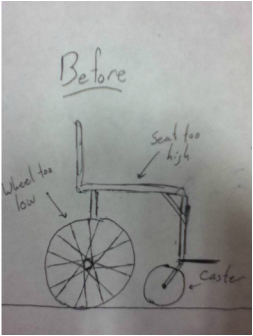

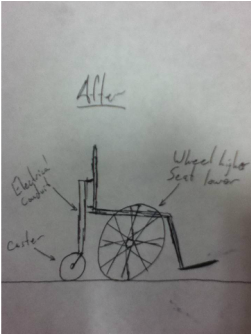

We hit a dead end earlier this week trying to mount the bicycle wheels on the wheelchair. The home-made casters we made push the chair up too high. The seat was at waist level and the bike wheels would them have to be mounted way too low in order to keep the chair level. This presented two problems: 1, A disabled person would have to climb in order to even sit in the chiar. 2, The user would have to have impossibly long arms in order to reach the wheels. We debated on how to solve this for quite some time. Things looked pretty grim, but my mom, Debra Mead, ended up finding a solution. She works as an Occupational Therapist at a local PACE program, and has to deal with wheelchairs, lifts, and motorscooters all the time. She suggested that we mount the turning wheels, the casters, in the back. I thought this through and decided it was the best solution. We will use cheap conduit to house the casters. and mount the bike wheels higher on the frame. This way, the foot plate can be as low to the ground as the patient wants, and the seat can be lower too.

Ok, so last week was a huge step for me. Remember how I said all the cadding and drilling and putting together of this project is not my cup of tea? Well, as it turns out, it's just not my usual cup of tea. Last week Daniel and I got to work carving out holes for our casters on the wheelchair, and we needed to bend the frame. I felt like a fish out of water surrounded by very scary, noisy, instruments of destruction. (I've used power tools an average of NEVER times in my life.) When Daniel asked me if I wanted to try working on the holes, I was nervous, but I decided that my days of being a sissy-girl were over. I drilled, I filed, I hammered, and most of all, I felt empowered as I excitedly watched my progress. I'm happy to report that I did 50% of all the manual labor on our wheelchair, and I really enjoyed it! This project is turning out to be quite the learning experience, in more ways than one!

The caster wheels are done. They are on the frame and work great. We ended up using a "T" connector for one of the axle mounts. It allowed us to easily insert the axle. Without it, we would not be able to fully assemble the wheels because all the connectors screw in.

According to my predictions, the hardest parts of this project are over. The fame is bent and those tricky front wheels are finished. The only challenge left is the bike wheels. I worked a bit on preparing them for the project. If all goes well, the whole thing will be finished by the end of the week. Vanessa is working on padding for the seat and back. This is important as it must provide the user with comfort and prevent pressure sores in long-term use. We are very happy at how smoothly everything has gone.

Me pounding away.

Ok, so there is one good thing about having a school that is under construction: you can hammer away at a piece of metal with a ball-peen hammer for an hour and nobody notices. That is what we had to do in order to crush the metal tubing of the hand truck enough to bend it into the shape of a chair. It involved a lot of noise and Vanessa and I both throwing all our weight into it to bend the thing, but it got done. The bends however are a weak point in the structure of the chair. We are planning on fixing this with triangular wooden braces to improve stability. The casters for the front wheels are done and fit perfectly in the holes we drilled. The project is looking more and more like an actual wheelchair every day.

Vanessa tries out the feel of the chair.

A lot has happened! We found all the parts we needed at ACE Hardware. Koodos to ACE. We are making the casters for the wheelchair our of steel gas line pipe. We got these parts from the hardware store but actual users in the third world would commonly encounter these parts around a junkyard or abandoned building. We decided against the rebar because after feeling it, we decided it was too weak and too rough to be an axle. The casters we are now using work PERFECTLY in the holes we drilled. Will post pictures soon.

RSS Feed

RSS Feed